|

| |

Performance advantage System structure Steel frame supporting Lateral force system Deck systems Interior wall system Exterior wall system |

|

|

Development of green low-carbon buildings without delay!

|

|

|

|

Global warming, polar ice melting, extreme weather disasters happen frequently. PM2.5 and haze seriously threat to human health and survival.

With the rapid economic growth, China's resources and energy consumption, waste emissions and environmental damage also will be a rapid increase,

The environment on our planet is suffering unprecedented pressure.

Construction sector overall energy consumption has far exceeded the industry and the transport sector, accounting for 46.7% of the energy consumption of the whole society;

With proceeding urbanization, the construction industry energy consumption growth is accelerating…

Saving carbon emissions is a global issue, and sustainable development is an eternal theme.

Building a beautiful China with 'sky blue, green, water purification', construction by low-carbon action should be without delay!

State council has issued a green building action plan which clearly defines what green building is: during the whole life of the building, maximize the resource conservation, environmental protection and pollution reduction, provide people with healthy, applicable and efficient usages of living space, and the building should be in harmony with nature. Furthermore to promote the prefabricated steel and other green building system at length.

As the country's only 'prefabricated high-rise steel residential national low-carbon technology innovation and industrialization demonstration base',

We are duty-bound to look forward to work together with you to achieve the goal of 'Beautiful China' with tireless efforts!

|

|

|

|

|

|

Reduction in carbon emissions: During the steel structure life time, the overall carbon emission will be 36.8% less than that by concrete structure;

|

|

|

|

|

Reducing environmental pollution: Industrialized production, prefabricated construction, 70% reduction in construction water consumption, more than 80% of waste water, dust and noise will be reduced;

|

|

|

|

|

Reduction in construction waste: About 70 percent reduced in construction waste when building up; 60% reduced upon the recycled main material during demolishing;

|

|

|

|

|

Industrial waste recycling: The success of new composite wall in the utilization of fly ash, tailings quartz sand, gypsum and other industrial waste

|

|

|

|

|

Indoor room rate increases: Because of the section reduction for tube concrete columns and thickness reduction in high performance composite wall, the efficient utilized area indoors will be 5.8% more;

|

|

|

|

|

Enhanced Seismic performance: The excellent ductility and seismic energy consumption performance of the steel structure itself, with less weight and other factors, the risk of brittle fracture of the building is cut to some extent, ensuring the goal of 'stand still in large-scale earthquake' to be achieved.

|

|

|

|

|

|

|

|

|

|

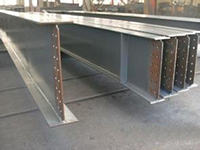

Welded square pipe concrete column

|

|

|

The welded square(rectangular) pipe concrete column is defined as such welded square steel pipe column filled with high strength concrete to form a structure member undertaking all kinds of loads from the outsides. The features are high strength, less column section area, less steel consumption, better plastic and anti-deformation capacity, better energy saving, better seismic undertaking, lateral stiffness, good steadiness, simpler construction without form supporting for convenience.

|

|

|

|

|

|

|

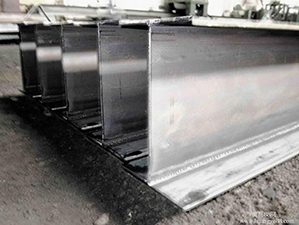

H-beam welding beam

|

|

|

Comparing to the traditional H-beam, the welding H-beam steel has advantages like larger model quantity at the section, with higher bearing capacity; higher flange width with larger lateral stiffness; more cost effective.

The sectional dimension is of highly flexibility. H-beam welding can be easily produced profiled H-beam (upper and lower flange width ranging from the upper and lower flange unequal thickness), so that the materials would be fully utilized.

H-beam welding production process features as high degree of automation, stable product quality, and high production efficiency.

|

|

|

|

|

|

Steel truss floor decks

|

|

|

Construction technology of the first generation concrete slab, its complex processes like scaffolding, formwork, and steel banding, furthermore the concrete curing long waiting period, would not adapt to the rapid construction requirements of steel structure; the second generation of the pressure plate concrete floor, due to the fixed bottom plates with rib height of 5-7cm, it is difficult to meet the housing conditions which need no suspended ceilings. Steel truss decks as the third generation, which is mainly industrial production and pre-fabricated construction, with no scaffolding nor wooden template, significantly reducing the requirement for steel banding amount, can be multi-constructed steel truss undertaking construction phase loads, construction quality and efficiency can be greatly improved.

|

|

|

|

|

|

Pre-fabricated Wall

|

|

|

Solution to the pre-fabricated wall:

Outside wall: which can be made of glass curtain wall or aluminum board, dry hanged stones; or fiber cemented integrated light weight grouting wall, would fully meet the current energy-saving emission-reducing standards, to realize the building energy-saving and industry waste utilization goal.

|

|

|

|

|

|

Anti-erosion and fire-protection steel members

|

|

|

Anti-erosion and fire-protection measures for steel members:

First, ball-blasting is done at the workshop for all the steel members; secondly, the surface will be painted by several layers of anti-rust paints (like zinc-rich epoxy, and epoxy micaceous iron); thirdly, the member will be painted with special fire protection after erection; lastly, fire-free plate or paste will be placed at the outside of the member, segregate the member thoroughly with the air, which is both decorative and practical.

|

|

|

|

|

|

|

|

Square(Rectangular) Pipe Concrete Column

|

|

|

1.Square (rectangular) pipe concrete column is defined as the welded square or rectangular pipe column or box column filled with high-strength concrete to form structural member bearing the outside loads.

2.Advantages of this type:

High bearing capacity and less steel consumption

The steel concrete member under the axial pressure plus the steel pipe restriction effect will be at the status of three-directional pressed, whose strength will be further enhance; because of the existing concrete, the pipe wall failure will be prevented at the early stage which will then fully make use of the steel bearing capacity. The two combined together with each other's advantages can enable the bearing capacity of the steel pipe concrete much higher than the sum of the individual pipe and the core concrete themselves. Under the same bearing conditions, the pipe concrete column will use much less steel than simple steel column.

|

|

|

|

|

|

Good plasticity and deformation capacity with better energy-saving capacity

The concrete is brittle, especially for the core concrete under the steel pipe restriction, the plasticity will be improved during the application stage, but also large plastic deformation capacity can be obtained when damaged; this structure tenacity is good when the compacting loads or vibration loads are applied.

Seismic performance

When combining with the concrete, the joint area with rigidity and high bearing of anti-shearing, the structure can avoid the disadvantages of pure steel columns under strong earthquakes or shear failure; CFST column frame structure, whose damping is larger than pure steel with strong energy dissipation. For plastic stage, strength and stiffness degradation is relatively slow, hysteretic envelope curve is plump, seismic performance is better than concrete frame. Under strong earthquake, it is easier to meet the requirements of the seismic mechanism of strong column with weak beam.

Lateral stiffness, good stability

Compared with pure steel columns frame, lateral resistance of concrete filled steel pipe whose column frame is with large stiffness, small lateral displacement, good positioning, good stability with less side effects.

Good performance

When caught fire, the concrete will absorb extra heat more than that of the pure steel structure, reducing the fire-protection treatment cost and stiffening working quantity after fired.

Convenient Construction

Compare with the rebar concrete column, the pipe concrete column needs not steel binding, and formworks, with simple construction method. Since there is no rebar in pipe concrete, the concrete placement will be much easier. Compare with pure pipe column, the pipe wall is thinner and lighter, which would reduce the transportation and hoist cost.

3.Implementation the standards of: "Technical specification for concrete rectangular pipe" (CECS159-2004), "the design and construction rules steel concrete structures" (CECS28-2012), "steel

Concrete Engineering Construction Quality Acceptance "(GB50628-2010), Technical Specification for Steel Structure of Tall Buildings (JGJ99-1998) and so on.

|

|

|

|

Steel Frame supporting system-welded H beams

|

|

|

1. Welded H beam is called upon the welding process for the H shape section of the member, SAW (submerged arc welding) and high frequency welding method are adopted.

H-beam using SAW technology: steel - Automatic Slitting - Assembling - automatic submerged arc - Testing - flange straightening - web Correction - face machining - sand-blasting - painting. Automatic submerged arc welding.Production line from cutting - assemblage - welding all controlled by computer to ensure the production of H-beam dimensional accuracy, weld quality have reached the national standard GB50205-2001.

High-frequency welding H-beam: high-frequency current by the local self-melting metal welding without wire, flux. High speed continuous production, high yield, easy to implement mechanization and automation. Same cross-section has an excellent cross-section performance.

|

|

|

|

|

2.Product advantages:

The more hot-rolled H-beam cross section modulus, high capacity;

Sectional dimension of flexibility and save steel consumption;

It can be customized on demand special steel, such as the upper and lower flanges of different width or unequal thickness and the like;

Beam - using full penetration welds, reliable welding quality

Making simple and can be automated continuous production, high degree of industrialization;

H-shaped steel beam web can open line hole, saving valuable headroom space, especially large-diameter pipeline basement space savings, its advantages.

|

|

|

|

|

|

Steel frame core tube system

|

|

Steel frame core tube system on the plane and the adaptability of the building facade is strong with lateral stiffness.

In elevator room or proper position, it is conducive to building fire, but also a good crowd walk reduce the impact of noise on residents of the elevator, effectively reducing the amount of steel.

Fabricated steel structure housing system by setting the steel columns, steel beams in the core barrel, the steel frame mounted on concrete tube construction, greatly accelerate the speed of construction and steel columns, steel beams

Reinforced concrete shearing wall type with a concrete wall, greatly improve the ductility of reinforced concrete shear wall, improve the seismic performance of buildings.

|

|

|

|

|

|

Steel frame supporting system

|

|

|

Steel frame supporting system is a high efficient dual stiffen system, profoundly improve the steel frame lateral stiffen and seismic performance. By steel supports effectively connecting to the column frame against the lateral forces, the structure can perform good seismic performance with rapid construction speed and systematic adaptation.

|

|

|

|

|

Structural features of the steel plate shear wall

|

|

Since the steel structure itself is light, it can reduce part of the seismic effect with cutting the basic cost.

The height-thickness ratio of the steel wall is usually from 100 to 500, with plate thickness ranging from 8mm to 40mm. According to some research, when the horizontal stiffness is the same, the steel consumption is less than that of the pure steel solution; the steel plate wall itself only undertakes the horizontal forces while the vertical forces are on the surrounding frame columns. The steel plate wall structure is completely conforming to the first round of seismic requirement with low axial pressure ratio, which is an ideal anti-lateral member.

The steel shear walls (both thin plate and thick plate) can undertake the loads after its failure, and not only the frame structure with good ductility, but also by the development of the steel itself plastic damping energy dissipation. Steel plate shear wall structure can ideally meet three standards of earthquake, the second stage of the design requirements;

Steel plate shear wall settings can be alleviated ductility of beam column joint area requirements;

Steel wall only lateral force on the wall fire resistance requirements lower than the corresponding frame structure, fireproof and anti-fire treatment of steel frame structures can be applied to steel wall structure.

|

|

|

|

|

|

|

Fabricated steel residential building retaining system ──deck systems

|

|

|

Along with social progress and the industry continues to move forward, from traditional hand masonry floor gradually industrialization, standardization of assembly. From the first, the second generation, to the third generation of development.

The first generation of floor ── situ concrete formwork floor boards

The first generation of slab formwork ── situ reinforced concrete slabs, suitable for low-level and multi-reinforced concrete. The floor to be used in steel house, faced with the following challenges:

1. The floor needs more cumbersome construction scaffolding, laying the template, tie bars and other manual jobs, their employment capacity, construction of low efficiency, long construction period, the quality of instability, it is difficult to adapt to steel

Quick construction characteristics and requirements;

2. The construction process must be layer by layer construction, while construction cannot meet the requirements for high level steel building;

3. The relevant specifications must meet the grade of concrete strength after 75% -100% before form removal, usually concrete curing cycle takes 9-15 days, after which the next layer before construction. For high-rise, high-rise steel construction project in terms of slowdown, the idling time is too long.

The second-generation floor ── combination situ concrete steel sheeting deck

To meet the fast characteristics of steel construction, the second generation of the floor decks came into being ── with ribbed high pressure plate (thickness 0.75-1.5mm) instead of the template. This floor system minus the scaffolding process and support template process more efficient than the first generation of floor construction has been greatly improved which can be widely used in public buildings. However, the floor will be applied to steel houses, still facing great challenges:

1. Steel banding process still needs to be done manually at site, which is still a large amount of work;

2. The pressure plate force participation as a permanent template cannot be removed. Pressure plate fin height of 5-7cm mostly steel, and residential projects due process high level roofing limit cannot do, thus it is difficult to accept this floor deck by the tenants.

The third generation of a floor slab of reinforced concrete composite truss Cast

To meet the development of steel housing, the urgent need to seek and steel "high, big, light, strong, and fast" phase matching, to meet the requirements of residential comfort solutions ── floor without scaffolding

And formwork, steel banding significantly reduce the amount of on-site and, ultimately, the bottom of the in-situ concrete floor effect equivalent level, to meet the "factory production and assembly of the construction" industry requirements, reduce site work capacity and increase the new floor deck system construction quality and efficiency. Thus, digestion and absorption of first-generation, second-generation floor advantages and disadvantages of the third generation of floor ── steel truss floor decks come into being.

|

|

|

|

|

|

Advantages of rebar truss deck industrialization:

|

|

1. The rebar truss floor deck is a kind of combined floor cover. When under construction, the deck is capable of certain construction loads similar to its self-weight; when under application, the rebar truss is integrated with the concrete body by its upper and lower strings of rebar to bear the working bearing together.

2. The rebar truss deck system thoroughly changes the traditional manual working methods. By industrialized and mass production and pre-fabrication construction, the wooden formworks are barely used, which also slowdown the environment pressure;

3. 80% of the site rebar working quantity is cut, and 60% of the site working quantity is also cut, which would solve the potential 'lack of labor ' problem;

4. The construction period is shortened by 30%, and thus the construction quality will be reliable and guaranteed, practically improve the innovation our country's construction technology.

|

|

|

|

|

Economic

1.Steel truss force mode, economic selections, and comprehensive cost advantage are obvious;

2.The steel truss height and diameter can be adjusted when applied to a larger span floor deck;

3.Wire provides rigidity to the construction stage, reducing the amount of steel and the relevant costs.

|

|

|

|

|

Convenience

1.70% of the site rebar banding quantity is cut;

2.No need of the scaffolding and formwork processes;

3.Simultaneous construction at different floors, 3D cross operation with different workers, shorten the working period at large.

|

|

|

|

|

Safety

1.Mechanical properties superior to traditional roofing board, with good crack resistance of the floor deck;

2.Fire resistance similar to that of the traditional ones, superior to pressure plate combination floor deck;

3.Bottom mold is not involved in the working stage for the stressing, so no need to worry about corrosion problems.

|

|

|

|

|

Reliability

1.Factories standardized production with steel arranged uniformly, precise size, distance between the upper and lower steel and concrete cover thickness reliable assurance;

2.Floor bidirectional stiffness similar advantageous to improve building seismic performance;

3.Stud welding quality assurance easier to avoid the destruction of galvanized steel corrosion layer is profiled steel plate for cored welding.

|

|

|

|

|

|

|

|

|

|

Fabricated steel structure housing a containment system- The interior wall system

|

|

|

Precast lightweight energy-saving composite wall

Residential energy-using precast lightweight composite wall, the wall has a solid, lightweight, thin body, soundproof, fireproof, waterproof, high strength, impact resistance, resistance to shock, hanging strong, thermal insulation, low-carbon energy, easy to cut, light weight, and good day, to achieve the comprehensive advantages of industrial waste recycling and so on.

The wall is mainly used for household walls, interior walls, exterior walls, fire walls, etc., can effectively reduce the wall area occupied, improve residential utility rates, reduce the building load, seismic and improve building safety performance, lower total cost, a quality substitute to the traditional solid clay brick. The wall can be slotted hang nail, dry operation, without plastering mortar, putty direct, convenient construction and other advantages, which is from a handmade steel residential construction masonry and wet behind the steering "factory production, assembly of the construction and integration of decoration," an important way to modernization of housing industry.

|

|

|

|

|

|

Product features for the pre-fabricated light green combined wall

|

|

|

|

|

|

Light/Economic

The light green composite wall is only 750 to 800 kg/m3, and the weight for 75mm thick wall plate is about 60kg/m2, 1/6 of the weight for brick masonry wall, 1/2 of the aerated concrete, or 1/7 of the 120mm thick masonry body +double plastered wall body. Hence, largely reducing the building weight and structure cost, increasing the usage area, with simple construction process and proper indoor arrangement for more functions.

|

|

|

|

Waterproof / moisture resistance

Energy-saving light composite wall using fiber cement board, has a good waterproof and moisture resistance performance, and therefore, the wall does not occur due to moisture absorption and release of the plate, back to halogen, deformation, strength loss and other phenomena.

Wallboard will not turn out condensate drops in wet weather, nor peeling plaster layer after a long time. Especially in the kitchen, bathrooms, basements and other damp places its advantage is particularly evident.

|

|

|

|

Fireproof

Energy-saving light composite wall at 1000 ℃ high temperature refractory limit of more than four hours, and do not emit poisonous gases, flammable performance up to the national A-level standards. After wall installation, with excellent stability and integrity, good fire resistance, fire and smoke can poison gas confined within the area affected by the fire, to prevent the spread of fire, toxic gas barrier (or to effectively isolate) so people have enough time to evacuate and the fire, to avoid significant loss of life and property, and 'prevention is better than rescue' fire theory.

|

|

|

|

Soundproof

Energy-saving light composite wall surface of the fiber cement board, the internal composition of the material, bump and groove connection between the board and the board have a good sound absorption and sound insulation. 90mm thick wall insulation reaches 40dB, much higher than other masonry wall sound isolation; sound insulation effect is in line with its national housing insulation requirements.

|

|

|

|

Earthquake / overall good

Prefabricated construction, triple structure, plates and plates connected together as a whole, excellent impact resistance, tested prefabricated composite wall is 1.5 times the normal masonry, and the overall seismic performance than traditional masonry wall a few times to meet the seismic intensity of more than eight architectural requirements.

|

|

|

|

Increasing the use of space

In accordance with the National Building partition board the relevant norms, lightweight composite panels 75mm and 100mm thick walls saving board can replace the traditional brick 180mm and 120mm thick, and the ratio of the thickness of the plaster after the full reduction compared to 85mm, which is that each extend 11.8 meters, increase 1 square meters of usable area, a room rate increased 4-8%.

|

|

|

|

High efficiency / Short duration / Construction Civilization

Due to dry completely prefabricated construction work, the wall height of 4 meters below, an average of one day be able to ship skilled workers more than 35 square meters, double-sided flat and no longer need plastering walls, installed after other decorations can simultaneously, wallboard can also be cut according to the building structure needs to adjust the width, length, reduce material consumption rate and construction waste; reach transportation simple, stacked health, without mortar, plaster, shorten the duration of effect.

|

|

|

|

|

|

|

Fabricated steel structure housing a containment system Exterior Wall Systems

|

|

|

Fabricated steel structure housing system has good adaptability, it can be combined with the functional requirements of the building, grade orientation, facades and other factors considered to select a different façade solutions, including: glass curtain Walls, stone curtain wall, aluminum curtain walls, as well as fiber cement board lightweight composite wall grouting system.

|

|

|

|

|

|

Fiber cement board lightweight composite wall grouting

|

|

|

|

Fiber cement board is the use of wall grout lightweight metal frame attached to the upper and lower floors and columns to form a continuous and stable light steel skeleton, internal and external sides, respectively, with medium-density and high-density fiber cement board, and cloth line the cavity between the keel and the board formed last hole pumped into light, heat lightweight aggregate concrete to form an integrated, solid and non-load-bearing lightweight composite wall insulation system.

|

|

|

|

|

|

|

Green light high-strength

|

Green

|

Low-carbon energy

|

Fire protection

|

Insulation

|

|

|

|

|

|

|

|

|

|

|

|

|

Moisture prevention

|

Light weight

|

Strong anti-impact

|

Hanging

|

Pipeline laying easy

|

|

|

|

|

|

|

|

|

|

|

|

Industrial waste

resource utilization

|

Pre-fabrication

construction

|

Seismic prevention

|

Stability

|

Anti-aging

|

|

|

|

|

|

|

|

Fiber cement board, based on wood pulp fibers, Portland cement, fine quartz sand, additives, water and other substances, the computer precise ingredients, beater molding, high temperature and pressure autoclave curing hydrothermal environment and stable crystalline form of high-tech, new wall materials.

External walls of high-density fiber cement board is the result of tons of press real pressure, high strength, low shrinkage swelling, flat and smooth surface, weather (freeze-thaw resistance, according to the anti-Japanese, anti-rain, durable, anti-leakage etc.) excellent performance. Therefore, the system with green, lightweight, high strength, thermal insulation, water proof, fire-resistant, anti-aging, impact resistance, wind pressure, the overall good, smooth surface, plane deformation and other outstanding features, and achieve pre-fabrication construction .

|

|

|

|

Lightweight Aggregate Concrete is a made of ordinary portland cement, sand (fly ash), lightweight aggregate insulation granules, additives and water and other materials made by mixing lightweight aggregate concrete, by pumping of fiber cement poured into the cavity between the plate and the keel to form a monolithic, solid non-load-bearing lightweight composite wall.

|

|

|

|

|

|

|

|